The Role of Welding Temperature Control

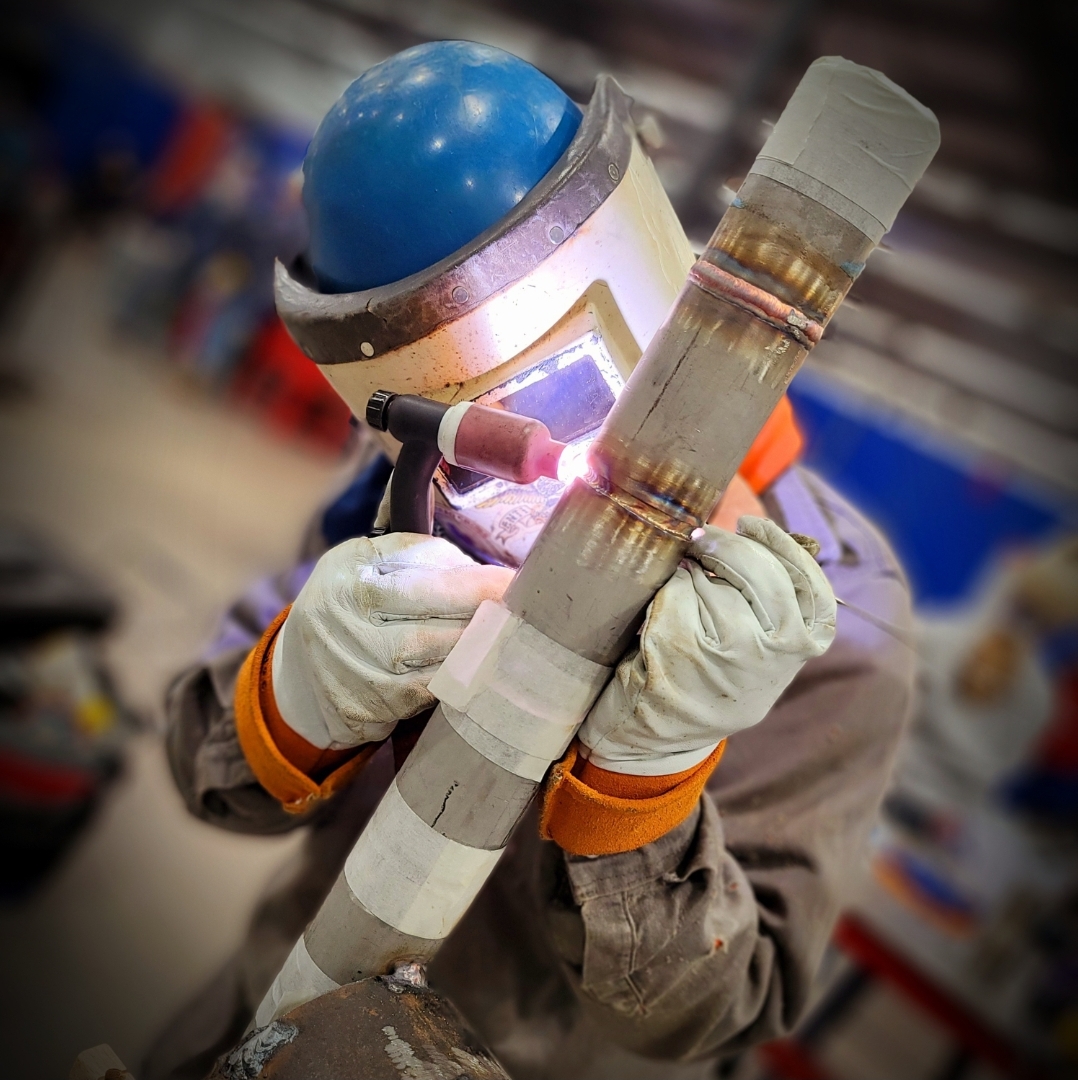

Welding is a craft built on precision, where every detail matters. Among all the variables that determine the quality of a weld, welding temperature stands above the rest. Get the heat right, and metal bonds cleanly and securely. Get it wrong, and you risk warping, cracking, or complete joint failure. Understanding how to control welding temperature throughout every stage of the process separates skilled welders from beginners.

Temperature shapes how metal behaves under the torch. It determines whether a joint will hold under stress, resist corrosion, or fail when it matters most. Learning to read, adjust, and manage heat builds both technical ability and professional confidence.

Why Temperature Control Matters

Every welding project depends on applying the right amount of heat at the right time. Too much energy causes distortion, burns through thin materials, or creates weak, porous joints. Too little leaves incomplete fusion and brittle connections that won't hold under load.

When welders understand thermal dynamics, they can anticipate problems before they occur. This knowledge reduces waste, improves efficiency, and creates safer working conditions. Temperature awareness turns guesswork into calculated decision-making.

Managing Heat Input During Welding

Heat input measures the energy delivered to the metal during welding. Controlling this aspect of welding temperature directly impacts the final result. Small changes in technique produce dramatically different outcomes.

Effective heat management involves several key factors:

Travel speed. Moving the torch slower increases heat concentration, while faster movement keeps the base metal cooler and reduces distortion.

Amperage settings. Thicker materials require higher current to achieve proper penetration, but excessive amperage creates unnecessary heat that damages the workpiece.

Arc length consistency. A longer arc disperses more heat into the surrounding area, while a tighter arc concentrates energy into the weld pool for better control.

Bead geometry. Wider beads distribute more heat across the surface. Maintaining consistent bead size improves both appearance and structural integrity.

Torch positioning. The angle at which you hold the torch determines how heat flows through the joint and affects penetration depth.

Mastering these variables gives welders precise control over their work, resulting in clean, repeatable joints.

Preheat and Post-Weld Heat Treatment

Different metals respond uniquely to thermal stress. Some materials need gradual warming before welding begins, while others require controlled cooling afterward. Both processes protect the metal's internal structure and prevent defects.

Welding temperature management extends beyond the arc itself:

Preheating. Warming the base metal before striking an arc reduces thermal shock and minimizes the risk of cold cracking in susceptible materials.

Interpass temperature monitoring. On multi-pass welds, maintaining consistent heat between layers prevents excessive hardening or softening of the heat-affected zone.

Controlled cooling. Allowing welds to cool gradually reduces residual stress and prevents brittleness that leads to delayed cracking.

Post-weld heat treatment. Applying controlled heat after welding relieves internal stresses that accumulate during the cooling process.

Temperature measurement tools. Using contact thermometers, infrared devices, or temperature-indicating crayons ensures accuracy at every stage.

Understanding when and how to apply these techniques requires training and experience.

The Critical Cooling Phase

Managing welding temperature doesn't stop when the arc goes out. The cooling rate determines many final properties of the weld. Rapid cooling can harden certain steels beyond their intended strength, making them brittle and crack-prone. Excessively slow cooling may cause grain growth that weakens the joint or allows distortion to set in.

The cooling phase also influences how well the weld resists environmental factors over time. Proper thermal management during this stage ensures the joint maintains its intended mechanical properties and service life.

Monitoring the cooling process requires attention to both time and temperature. Experienced welders know that this final step often determines whether a weld performs as designed or fails prematurely.

Recognizing Material-Specific Welding Temperature Responses

Each metal has its own thermal personality. Aluminum conducts heat rapidly, requiring quick work and higher heat input. Stainless steel retains heat and demands careful control to avoid distortion and carbide precipitation. Carbon steel's behavior changes with its composition, particularly its carbon content.

Understanding these differences comes from observation and practice. The color of the metal as it heats, the fluidity of the weld pool, and even the sound of the arc provide real-time feedback. These subtle indicators guide experienced welders as they adjust their technique on the fly.

Reading these signs accurately develops through hands-on repetition and deliberate attention to what's happening in front of you.

Building Skills Through Practice

Controlling welding temperature is more than following rules. It's a combination of technical knowledge and developed instinct that comes from repeated practice. Each project teaches new lessons about how heat moves through different geometries, thicknesses, and material combinations.

The best welders take pride in their ability to produce strong, reliable joints consistently. This pride comes from understanding the science behind the sparks and applying that knowledge with precision.

If you're ready to develop these skills under professional instruction, the American Welding Academy offers comprehensive programs that combine classroom learning with extensive hands-on training. Our courses teach students to manage every aspect of the welding process, from heat control to finishing techniques, preparing them for successful careers in the field.

Choose from our 24-week Pipe Welding & Fitting Course or 12-week Fabrication Welding & Fitting Course, both led by world-class instructors who provide the hands-on experience and industry expertise employers demand. With day and evening sessions available and new classes starting throughout the year, you can begin building your future on your schedule. Contact us online or call (636) 800-9353 to learn more about enrollment, program details, and how we can help you launch a career that lasts.